How To Repair A Cantilever Deck

There are thousands of cantilever decks in the San Francisco Bay Area. Due to age and lack of maintenance many of these decks are failing and presenting life rubber issues. A failed cantilever deck was responsible for the tragic accidents in Berkeley a few years ago. Golden Gate enterprises specializes in repair and replacement of cantilevered decks in the San Francisco Bay Expanse. We accept a dandy deal of expertise and accept completed many projects. We handle plans, permits, and engineering. Repairs frequently require opening upwardly floors, ceilings, and building facades. You need a very experienced General Contractor for this type of project.

Postal service & Beam Deck Structure

Cantilever decks are used extensively beyond the United States. Here in the San Francisco Bay area, we run across thousands of decks using the cantilever method. When nosotros consider deck construction, at that place are more often than not two types for raised or elevated decks; post and beam structure, and cantilever construction. You accept all seen mail and axle structure. In the simplest form in that location are several posts that are secured via piers to the ground, and these posts come up to support the principal beam that holds up the exterior of the deck.

Post and Beam Deck Construction

Cantilever Deck Construction

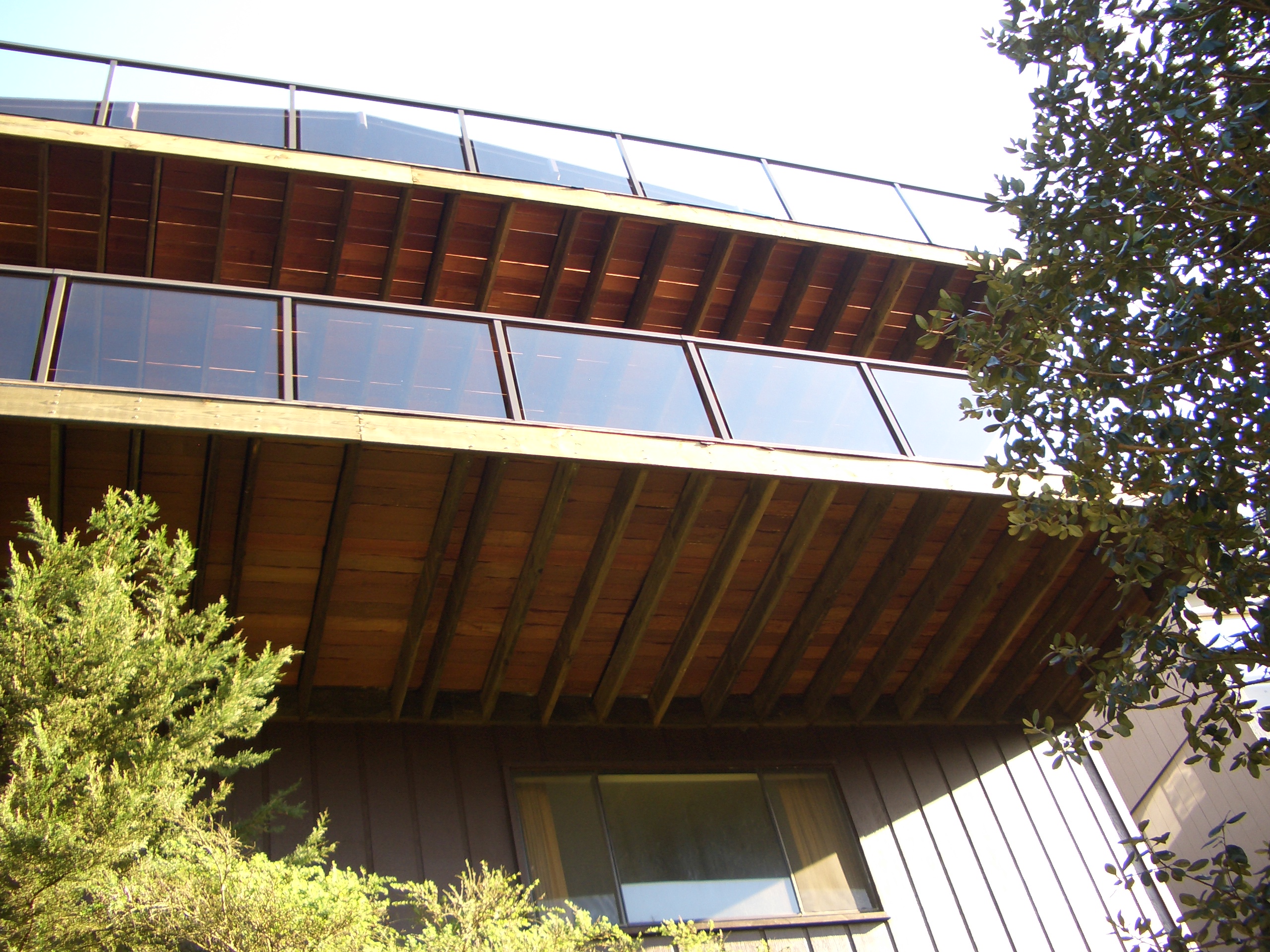

A cantilever deck is ane where the support of the deck joists is actually from an extension of the floor joists from inside the house. At that place is no mail and beam to support the joists. The structural integrity of the deck is derived from the size of the joists, the blazon of wood, their projection from the structure (your house) and ultimately how the floor joists are secured within your building. Cantilever decks are a clever thought, only can nowadays bug if not carefully constructed and maintained . Don't confuse a true, fully cantilevered deck (no posts/no axle) with a small partial cantilever of deck over a post and beam structure. A truthful cantilever deck has no posts and beam.

Cantilever Deck (no external posts and beams)

Rotted Cantilevered Joists

While the benefits of a cantilever deck may exist obvious…no posts and beams to obstruct your view, they practice present problems. Nigh frequently cantilever decks are constructed during new or original structure. Why ? Considering information technology may be convenient to extent the house floor joists out further to create a deck, or tie into the house framing. The big issue with cantilever decks is the hazard of the joists rotting over time. If the joists are rotted, and compromising the structural integrity of the deck, so the choices are limited in repairing the deck.

Rotted Cantilevered Joists

Replacement of Cantilevered Deck Joists

Cantilever deck joists can merely be replaced by going dorsum in to house (yes opening up the ceiling or floor) approximately 2 feet for every one human foot of projection outside the firm (engineering details required here). The real signal is that the operation is invasive, labor intensive, and expensive. Converting over to a post and axle structure as part of the repair may be an alternative, merely oftentimes this creates other issues and is not necessarily less expensive. At present yous have posts and a beams obstructing lower area views. As well a change from the original deck structure will likely trigger the need for a fix of engineered plans (in California..everything requires an engineer…), plan checks and reviews. Virtually times its easier and smarter to stick with a repair of the original structure. Hither is a typical scenario. A deck 20 years old is determined to have rotted joists. Where do joists rot ? Of grade at the very top right under the deck boards. It's a horizontal surface that should accept been waterproofed or flashed during original structure. It'due south astonishing how many contractors skip this detail. The flashing is not required by code, and then many simply skip this because of the added cost, or they merely don't understand the issue. A significant portion of our company projects (Golden Gate Enterprises, Inc. San Francisco Bay Area General Contractor) are deck structure repair and replacement projects as well every bit dry out rot and structural repairs. Most of the failures brainstorm with leaks, and the ultimate rotting of the joists and beams that were never flashed properly.

Replacement of Cantilevered Joists Requires Opening Ceiling Within Business firm

Plumbing Must Be Removed and Re Connected

Joist Axle Deck Flashing

Experienced General Contractor Required

Repair and replacement of cantilevered decks requires the skills way beyond that of an average deck builder. Consider that you volition have to open up the siding (wood or stucco), slide in new joists, make an engineered connection to the existing joists/framing, remove/re-install wiring, plumbing, ducting, remove/supersede sheet rock with record/texture/painting, waterproof the penetrations through the outside of the house…then of cours rebuild your deck. In short, you need a very experienced full general contractor that specializes in cantilever decks. Repair and replacement of cantilevered decks are not inexpensive. Our company has had to redo many cantilevered decks that were washed by inexperienced contractors….and homeowners thinking they were saving a picayune money. This is the place to store for feel, not price.

Incorrect Forest For Joists Exterior of The House- Doug Fir Is Not Adequate

Another interesting observation…many cantilever decks are using longer " in the house" flooring joists that project outside the business firm to create a cantilever deck. Why practise I mention this ? Because the vast majority of times the woods used is the standard doug fir that is acceptable for interior use….but is the concluding forest you want to utilise for exterior use. Once doug fir gets moisture and starts to rot…it moves quickly. The standard save money approach is .."oh we will just pigment information technology". Our arroyo is to use pressure level treated wood for cantilevered joists. In the past, other atmospheric condition resistant wood species…like redwood were used, but those days are fading rapidly for a number of reasons (cost, quality, engineering specs, etc). The determination is to use pressure level treated joists with proper flashing over the elevation before decking is installed. If you having new construction done, don't let anyone convince you its ok to have doug fir joists for your cantilever deck. While this washed most often, observe a good contractor or good architect and they would NEVER exercise this at their house. See the pictures above of the new joists installed adjacent to the old joists. Note the pressured treated forest is a different colour than the original doug fir wood.

Proper flashing is another item worth mentioning. We accept seen many types of flashing details over the years. One of the worst is using basic sheet metal. While the idea seams ok, the problem is that when deck screws/nails from the decking penetrate through the metal flashing, information technology creates a path for water to drift under the metallic flashing…and do its chore of rotting out the joist over time. The right solution is to utilise a flashing fabric that has cobblestone/tar based backdrop that stick to the top of the joist AND are self sealing with nail/screw penetrations. And I really need to stop using "blast/screw" because the best mode secure decking is with screws..not nails. Nails have a fashion of "popping" over fourth dimension creating cruddy decks, cut your human foot stick ups, and a path for water to become into the deck boards and joists. If you have a cantilevered deck, consider some strong preventative maintenance. Before yous have a problem, supersede your decking. In the process, waterproof the tops of the joists properly so y'all will accept many years of "don't worry about it" protection on your deck joists. However, exist prepared to detect "hidden" rot when you pull upward the deck boards. If the deck is more than 10 years old, I have yet to pull upwards deck boards and not discover rot on the top of joists. If the joists are nevertheless structurally audio, the remedy is to treat the joists with a special two part penetrating epoxy. Penetrating epoxy is another discussion area, merely nosotros volition save that for a after commodity.

Waterproofing A Cantilevered Deck

Spending at present to supervene upon your decking and protecting your joists will probable save you lot many thousands of dollars in future deck replacement. Another consideration is waterproofing the deck surface. As a leading San Francisco Bay Surface area waterproof deck contractor (remember decks over living space, balcony decks, waterproof membranes, Duradek , waterproof tile decks, etc) , we ofttimes offering the culling to convert the deck to a fully waterproof deck. Instead of deck boards going back, plywood goes down, so our waterproofing system. At present you volition never worry near water rotting out the deck. In addition, you will now accept a covered space below the deck. See the video below for examples of this solution. There are of import details that come up along with this solution. The biggest issues to accost properly is adequate slope on the deck. Flat decks do not bleed, so proper sloping of one quarter inch per foot has to be designed into the deck.

Let'south see a few videos of cantilever decks..

The video above is a full walk through of a chore. Lamentable..no audio on this one. I am in the process of redoing this with narration.

And await at this video below…a failed cantilevered deck. And you idea you have bug…and no the woods you see is Non a postal service and beam system..information technology is a temporary support to forestall the deck from falling down !

The conclusions from this brief article area as follows:

New cantilevered deck construction: Become information technology designed properly from the commencement to foreclose future problems. Most architects/builders don't get the details washed correctly.

Current Cantilevered Decks: Get on with preventative maintenance before it turns into a very expensive problem.

Repair/replacement of existing cantilevered decks: Be certain to become a very experienced contractor that specializes in this area.

Golden Gate Enterprises Inc San Francisco Bay Area Full general Contractor Specializing In Cantilevered Decks, Dry Rot, Deck Structure, and Waterproof Decks

Paul Gordon is the President of Golden Gate Enterprises, Inc a leading San Francisco Bay Area Full general Contractor that specializes in deck blueprint, deck construction, deck repair, cantilevered decks, waterproof decks, dry rot repair, structural repairs, and full construction services. The company provides engineered plans, permits, and full construction services. Gilded Gate Enterprises can exist reached at 510-885-0197.

PRESS Hither if you would like to request an appointment for your project. I promise yous have found this commodity informative and helpful. All of my articles are derived from in field real world experience of many construction projects.

This cantilever deck has pregnant rot and is condign a life prophylactic issue. Time for replacement. Call Paul at Golden Gate Enterprises for a complimentary consultation 510-909-8552.

How To Repair A Cantilever Deck,

Source: http://bayareacontractor.com/cantilever-deck-repair-replacement/

Posted by: grahamsheining.blogspot.com

0 Response to "How To Repair A Cantilever Deck"

Post a Comment